KEGLINK FEATURE: Temperature

The metrics our KegLink sensors monitor are not randomly chosen. Each is individually important to the storage and delivery of great beer, and combined they provide a multitude of measures that are useful to brewers, sellers and drinkers alike. Temperature is arguably the most important metric when it comes to beer, so how it is measured is especially critical.

Choosing a Temperature Sensor

In choosing which temperature sensor to include in KegLink we took into consideration several factors.

- Accuracy. Accuracy is only important in relation to the purpose. As an example, when tracking medical samples a 0.1 degree celsius (0.18°F) can be the difference between detecting a disease or not. Thankfully beer is not as life and death, but we still measure it down to a fraction of a degree.

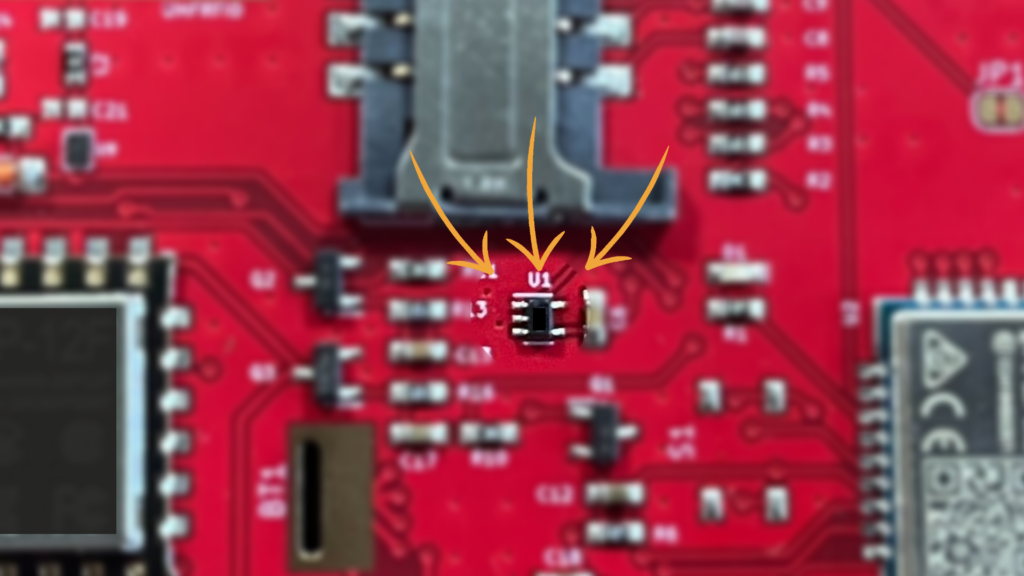

- Power Consumption. Our goal is to reduce the amount of power required to run KegLink as close to zero as possible. This is so that the battery life is as long as possible and the devices don’t need to be maintained as often. While the average digital watch uses around 5uA (micro amps) of current, our chosen temperature sensors on KegLink consume less than 1uA.

- Availability. Making sure we can get the temperature sensors is obviously important. Given the technical nature of the sensors, we have to make sure they’re not an “end-of-life” product, about to be redundant or unavailable in the current global electronics component shortages.

- Compatibility. Anyone who’s ever tried to use a mac and a pc or android in the same day knows how tricky it can be to switch between them. KegLink’s temperature sensor is one of nearly 100 components on the circuit board so the ability for those components to work together is critical to KegLink’s reliability.

- Price. We’re not bargain hunters, but we do want KegLink to make financial sense for brewers monitoring their entire keg fleet. In that way, cheaper is better, but we won’t be compromising reliability, or any of the above factors.

Interesting Features

One thing most people assume when they first hear about beer monitoring is that the beer within the keg has a thermometer or other measuring device inside the keg. Surprise! KegLink doesn’t do that. Aside from a whole heap of food production safety headaches, we found this would be an inferior solution anyway. Beer has high specific heat capacity, meaning temperature changes inside a full keg typically happen quite slowly. By measuring the temperature external to the keg, our temperature reading acts as a lead indicator, giving deeper insights into the supply chain, and a window of time in which to intervene before the beer itself is affected and written off as waste.

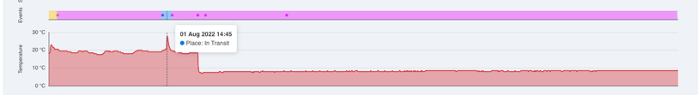

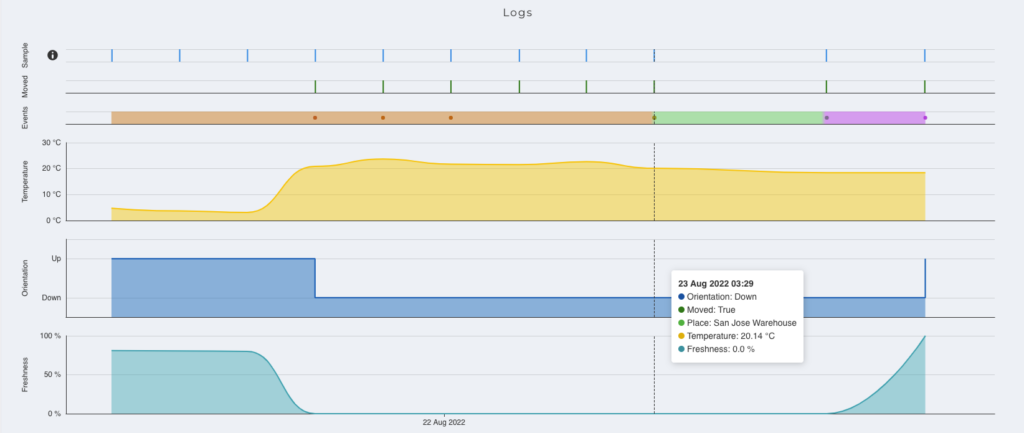

Another thing we noticed was the rhythmic fluctuations in cool room temperatures. What can we say, we’ve spent a lot of time in cool rooms at venues and breweries! While outdoor kegs typically see day and night temperature swings over a 24 hour period, kegs inside cool rooms typically see a much faster cycling of temperature as the refrigeration unit starts and stops. This is a tell-tale sign that the keg has made it into a cool room which our software automatically detects, along with the obvious shifts in temperature when the keg enters and leaves a cool room.

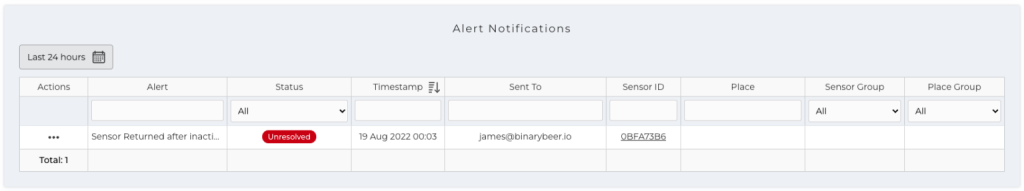

Examples of Custom Alerts

As well as the built in Cool Room alerts, it is easy to set up your own alerts to monitor things that are important to your brewery.

- Fill Status + Extreme Temperature Changes. As the temperature readings are taken from the keg rather than the beer, they actually run a little ahead of changes to the beer itself. This means you can set up an alert to monitor if your filled kegs are about to freeze. Time to ring the venue and tell them to bring the kegs inside before they are potentially destroyed.

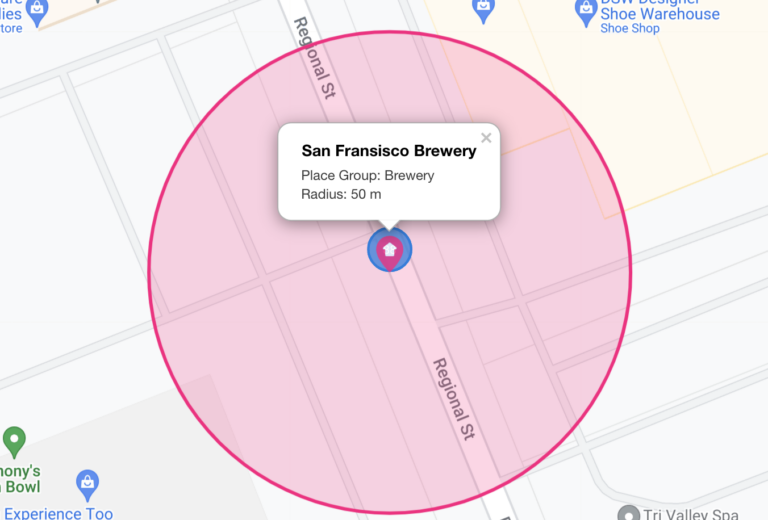

- Temperature + Geo Location. An alert can be set to monitor where you kegs are, and what temperature they are. This gives you visibility on the transportation of your kegs. Whether they’re being kept nice and chilled in a refrigerated truck, been left sitting outside a venue, or maybe they’ve spilled onto the roadside.

- Temperature Change + Coupler Detection + Orientation. One of the more obscure alerts we’ve seen is the combination of a spike in temperature, a coupled keg, and an upside down orientation. Can you guess what’s going on there? Typically this indicated that the keg is being cleaned.

Temperature is the main variable in the Arrhenius Equation, (a formula that can be used for calculating beer freshness based on the chemical reactions occurring in packaged beer). Monitoring temperature is crucial to ensuring brewery to bar freshness.

KEGLINK FEATURE: Orientation

The metrics our KegLink sensors monitor are not randomly chosen. Each is individually important to the storage and delivery of great beer, and combined they provide a multitude of measures that are useful to brewers, sellers and drinkers alike. Orientation may seem a little odd to include in our metrics, but it is a powerful measure that can indicate so much more than “this way up”.

Upside down.

Unlike filtered and pasteurised lagers, some beers are meant to contain a bit of yeast in the keg. In some cases, a light dusting of yeast is added during the kegging process, allowing beers to carbonate and “condition” inside the keg. Furthermore, some beer styles are meant to be served with a nice visible dose of yeast in suspension, adding to their appearance and flavour profile. The process of flipping a keg throughout its journey can keep yeast distributed evenly, and prevent unsightly clumps forming that could otherwise make it into the glass.

Sometimes the orientation of a keg has nothing to do with preserving the beer inside. In some supply chains, upside-down kegs signify a keg that is empty and ready for collection. This is a simple way to separate ingoing vs outgoing kegs making life easier for delivery drivers.

Another situation where kegs are typically flipped upside down is inside the brewery when they’re loaded onto a cleaning machine, or an automated filling line.

Whatever the reason behind it, Binary Beer’s KegLink is able to tell you when a keg is upright or upside down, along with a multitude of other indicators.

How does KegLink determine upside down?

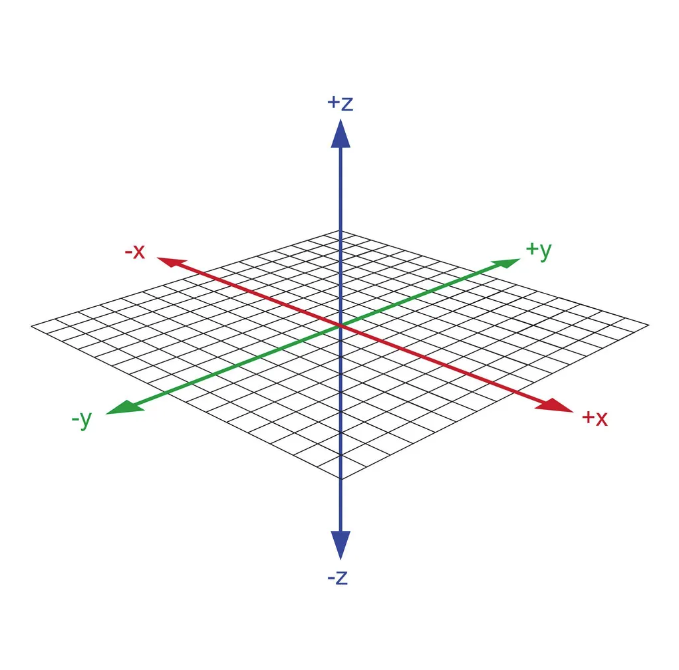

KegLink sensors are equipped with a 3-axis MEMS accelerometer to determine orientation. Easy right? Just plug it into the circuit board and away you go. Not quite. Typically kegs don’t have a level top plane on which you can neatly secure a device. There’s also around a dozen different styles of kegs, each with their own special profile.

A MEMS (micro-electro mechanical system) accelerometer can measure line motion across any set number of axes without a fixed reference point. KegLink’s axes are set up to compensate for the angles of both the device and the installation atop a keg.

Currently KegLinks are built to indicate an upright or upside down orientation, but there is no reason we couldn’t flag 90 degree turns, or 45. If you need it, Binary Beer is up for the challenge.

KEGLINK FEATURE: 'Has Moved'

The metrics our KegLink sensors monitor are not randomly chosen. Each is individually important to the storage and delivery of great beer, and combined they provide a multitude of measures that are useful to brewers, sellers and drinkers alike. One built-in measure that comes standard is ‘has moved’.

The lifespan of a keg is full of hustle and bustle. From brewer, to pallet, to truck, to fridge, to conveyor belt to venue chutes – kegs get treated pretty rough. Yet you may be surprised to learn how much of a sedentary life kegs live between these important events, spending days, weeks, months, or (yes we’ve seen it) years without being touched at all. One of the key flags built in to our KegLink software is the ‘has moved’ indicator, which is indicated by the same MEMS accelerometer that detects orientation.

The ‘has moved’ flag signals when a keg has physically moved, like being loaded onto a pallet, shuffled around in a cool room, or travelling along a potholed outback road to a terrible place like a pub with no beer. These slight movements are critical to understanding the keg’s whereabouts in the supply chain of beer. The 3 axis accelerometer is critical in detecting small motions in all directions.

Determining the ideal motion thresholds involved a lot of heavy lifting, transporting and a few sore toes (kicking empty kegs around the brewery). We knew we had a good compromise at a sensitivity threshold 800 milligals, when there were zero false-triggers on a stationary keg, but the keg also couldn’t be snuck out the door without setting off the “has moved” flag (picture Binary Beer staff dressed as sneaky cat burglars stealing kegs of beer).

Capturing a keg’s movement throughout the supply chain is a little more tricky than checking orientation, since some keg movements span just a few seconds. This means the accelerometer must be running constantly throughout the life of the sensor, ever vigilant, waiting to capture that next tell-tale jostle.

We put a lot of R&D into the algorithms and circuit design to optimise power usage while still capturing valuable fine-grained details. In the end, this feature consumes <1uA which is about enough to drain a AA battery in 228 years.

If you want to know your beer is the freshest it can be, contact us via [email protected]

Fresh Insights and Fresher Beer. Binary Beer.