Production planning in brewery can be a challenging task. With the increasing demand for craft beer, breweries must ensure they produce enough beer to meet the market’s needs. However, overproduction can lead to wastage, while underproduction can lead to lost sales.

This blog post will discuss production planning and how data can help streamline the process.

1. Production Planning in Brewery Process: an Overview

1.1 5 steps in the production planning process of a brewery

Step 1: Breweries must forecast demand based on confirmed and predicted orders.

Step 2: Determine production options by mapping out the steps of your process and analysing the resources required.

Step 3: Choose the option that maximises your operational capacity while also covering costs

Step 4: Monitor and control the process to quickly address any problems that arise

Step 5: Always be prepared to adjust the plan if needed, and have a risk mitigation plan in place.

1.2 Challenges that breweries face in production planning

Planning is crucial for the success of any business, including breweries. Without a good plan, brewery owners may waste time and resources, ultimately affecting their profitability.

However, one of the biggest challenges that they face is accurately forecasting demand. This can be particularly difficult because market trends are constantly changing.

Furthermore, determining production options that are feasible within the available resources presents another challenge. Brewery owners need to take into account various factors, including the capacity of human resources, machinery and equipment, materials, and inventory. Only then can they make informed decisions about how to best allocate their resources to meet the demand for their products.

2. Data makes production planning in brewery easier

One way to make production planning in brewery easier is by using data. For example, by analysing past sales data, you can identify trends and patterns in demand. This information can help you plan production schedules that align with market demand.

2.1 How live data on market demand helps?

2.1.1 No more underproduction and overproduction

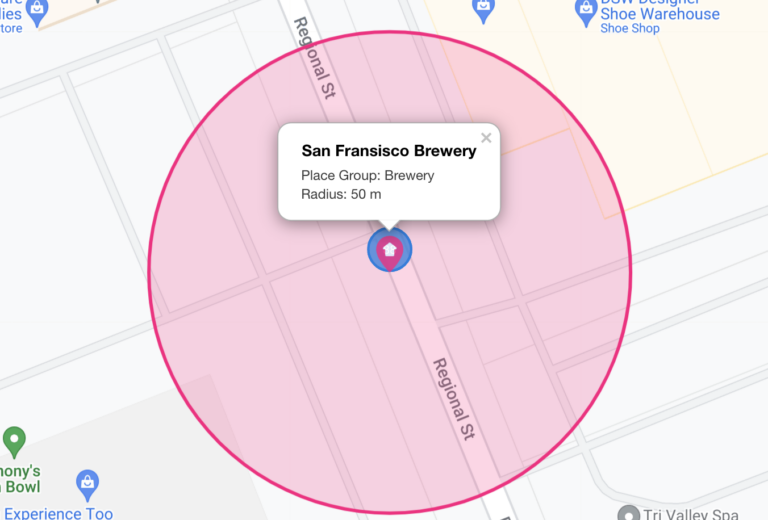

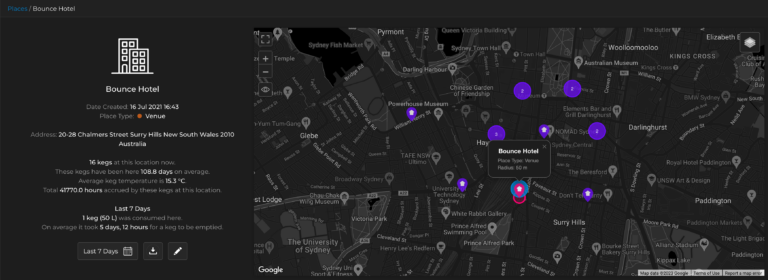

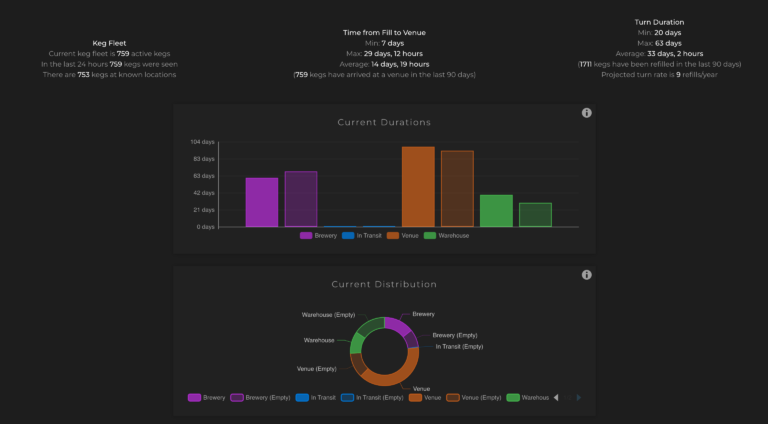

Live data on market demand can be particularly useful for breweries looking to avoid underproduction and overproduction. Data from logistics channels, warehousing, and distributor stock levels provide valuable insights that help breweries quickly adjust their production schedules to keep up with changes in demand. This helps avoid situation where is in short supply or where excess inventory is sitting idle. Additionally, by optimising production in this way, breweries can also save on costs and resources, ensuring that they are making the most of their investments.

2.1.2 Improve customer satisfaction

Data-driven decision-making in market demand also helps breweries improve customer satisfaction. Isn’t it great, in your production planning process, you already ensure that you keep customers happy? By tracking customers’ behaviours, breweries can better understand what types of beer are most popular and adjust their production planning accordingly.

Besides, having real-time, direct data about customer stock level helps breweries avoid weekly, and monthly sales calls – which can be a bit annoying (to customers) sometimes. Now, when talking to customers, the sales team in brewery can have a thorough understanding of customers, which makes the conversation easier and more efficient. Customers always have access to their favourite beers and new products are introduced in a timely and strategic manner.

2.2 How live data on beer quality control helps?

In addition to market demand, live data on beer quality control can also play a crucial role in production planning.

By monitoring beer quality in real time, breweries can identify potential issues early on and take corrective action to avoid quality problems down the line. This can help reduce the risk of product recalls and other quality-related issues, which can be costly and damaging to a brewery’s reputation. Breweries can also guarantee that their products meet the highest standards of quality. This can help build trust with customers and ensure that breweries maintain a positive reputation in the industry.

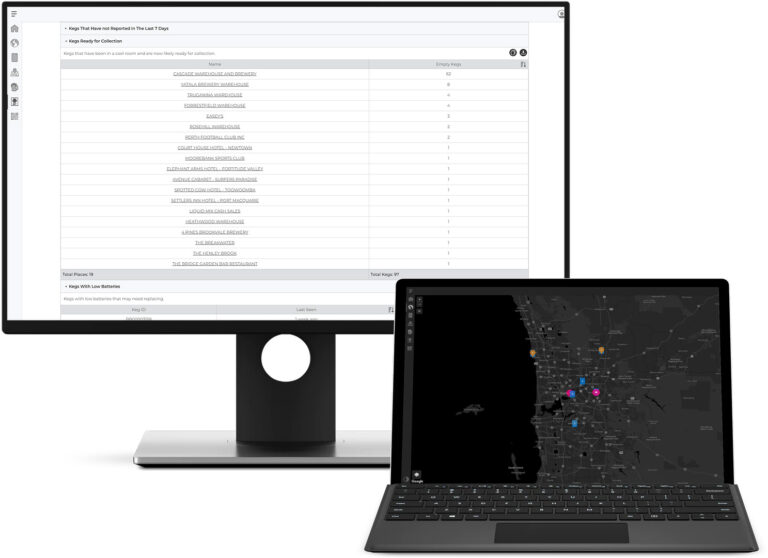

3. Binary Beer offers an analytics platform for breweries

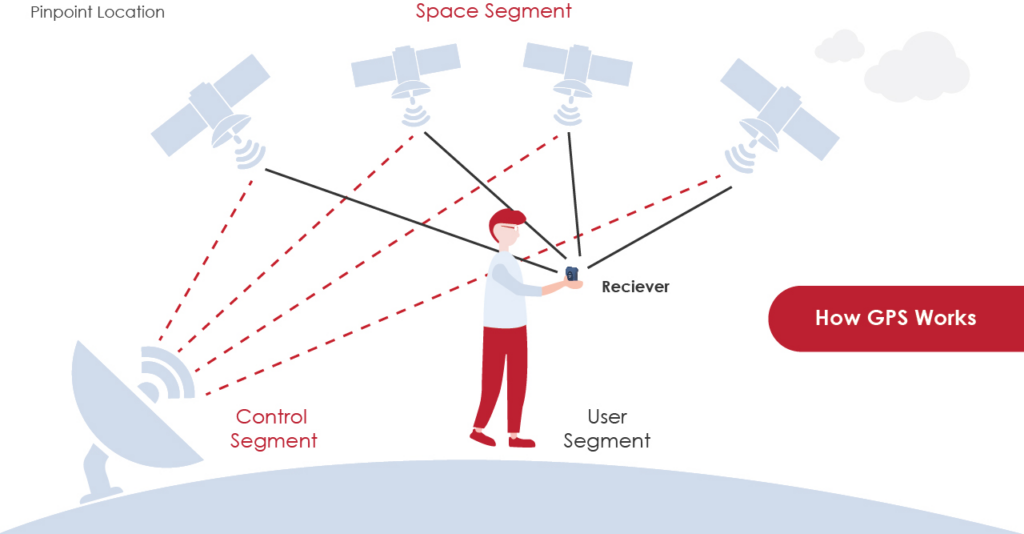

Our proprietary draught beer insights platform is an extension of our KegLink IoT stack that offers a comprehensive understanding of all aspects of draught beer management. BinaryBeer enables us to gain valuable insights into optimising logistics, boosting sales, and achieving sustainability targets. KegLink is the missing key to unlock valuable data and drive digital transformation in the brewing industry.

You need a customised demo and learn how to stay on top, reach out to our best tech experts here.