Take 3 minutes to read this and you could save thousands in new keg costs

Step 1:

Map your supply chain

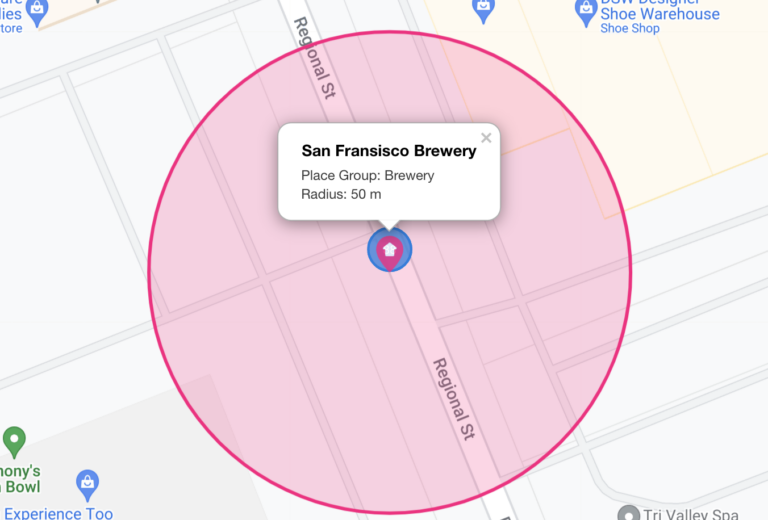

Take a moment to map the journey your keg takes from your brewery to the tap & back again.

This is the backbone of how most breweries plan their business operations and logistics costing.

Step 2:

Time your supply chain

For each stage in the distribution cycle, assign the length of time it should take a keg to pass through this stage.

Remember, we’re working with averages here, close enough is good enough! You may end up with something like the timeline below.

Step 3:

Rate your supply chain

Now it’s time to look to your sales records…

How many kegs of beer did you sell last year?

How many kegs are in your fleet?

For our example above, let us assume we sold 400 kegs in a year, and we have 100 kegs in our fleet.

Our numbers of turns would be 4 per keg and our average turn would be 91 days.

If you feel confident that your timeline is correct and that your current Number Of Turns is the same or similiar to your Expected Turns Per Year; then you should buy more kegs.

If not, then you should consider optimising your existing fleet.

What does this mean? Take a look back at your numbers…

At step 2 you determined how many turns your kegs should make each year.

At step 3 you calculated how many turns your kegs do make each year.

By dividing the answer at step 2 by the answer at step 3, then multiplying by 100, you calculate the extra capacity in your existing fleet.

For example:

Example A 8

--------- x 100 = - x 100 = 200% Capacity

Example B 4

i.e. This brewer could be making double the sales with their existing fleet!

But how?

Usually brewers look to buying more kegs when they are already struggling to get kegs in the door to be refilled. How can they get more sales out of their current fleet?

More importantly, how can you?

With KegLink!

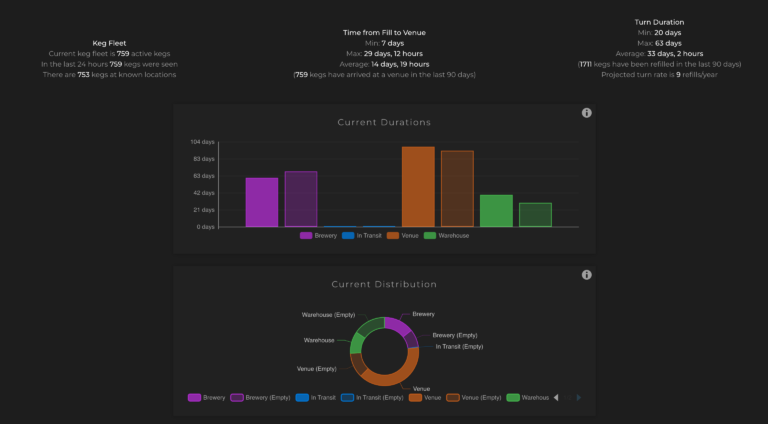

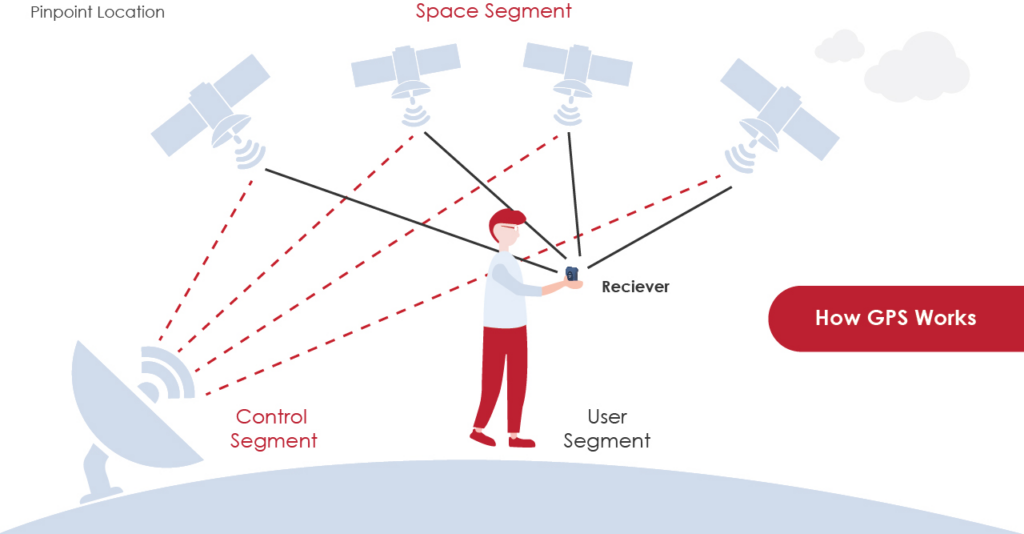

KegLink keeps track of your kegs 24/7, reporting back to you no matter where they are in their ‘journey’. With simple actionable reports and customisable alerts, you have all the information you need to get your kegs moving and keep them moving, speeding up your keg turns!

What would doubling your sales mean to your brewery?

In our example:

Assuming 20% profit margin on a $240 sale price

100 Kegs x (8 Optimised Turns - 4 Existing Turns) x 20% Profit x $240 Sale Price

= $24,000 additional profit

I can hear your thoughts, you’re thinking ‘sure, but now I’ve got to make those sales‘, and you’re right. Check out our benefits page to see how KegLink can help you sell more beer, and use these calculations to see just how much effective your keg fleet could be.